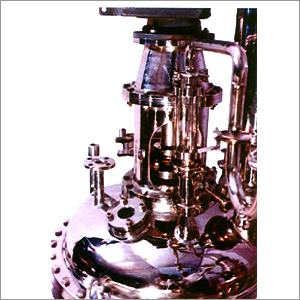

Storage Tanks

200000.00 आईएनआर

उत्पाद विवरण:

- शर्त

- प्रॉडक्ट टाइप Storage Tanks

- सामान्य उपयोग Liquid Storage (Water, Chemicals, Oil, etc.)

- मटेरियल

- क्षमता 1000 to 50,000 Liters

- वजन (किग्रा) Variable as per capacity

- कम्प्यूटरीकृत

- Click to view more

X

स्टोरेज टैंक मूल्य और मात्रा

- 1

- यूनिट/यूनिट

स्टोरेज टैंक उत्पाद की विशेषताएं

- Storage Tanks

- 1000 to 50,000 Liters

- Customized

- Variable as per capacity

- Liquid Storage (Water, Chemicals, Oil, etc.)

स्टोरेज टैंक व्यापार सूचना

- 10 प्रति सप्ताह

- 4-5 महीने

- नालीदार बॉक्स में पैकिंग, सिकुड़ते हुए रैपिंग और लकड़ी के बक्से उपलब्ध हैं।

उत्पाद विवरण

We are the leading manufacturer, exporter and supplier of high quality Receivers & Storage Tanks that are used in oil refineries for the storage of oil and chemicals. These are available in various capacities and are manufactured with high precision using the finest quality raw material and modern methodology. Our clients can also avail these Receivers & Storage Tanks in various customized options at market leading prices.

Features:

- Rust resistance

- Durability

- High strength

- Ruggedness

Technical Specification

|

Capacity |

500 Ltrs to 300000 Ltrs |

|

Diameter |

500mm |

|

Design Pressure |

Upto 700 kg/cm2 g |

|

Design Temperature |

Upto 160 degree C |

|

Empty Weight |

72 Tons |

|

Standard Codes |

IS2825/ BS 5500/ API 620 |

Versatile Storage Solutions for Diverse Liquids

Our storage tanks cater to a wide spectrum of liquid storage needs, from water to industrial chemicals and oil. Reliable for both industrial and commercial applications, they are available in multiple configurations, including horizontal and vertical installations. Crafted for longevity with superior materials and corrosion-resistant finishes, these tanks ensure secure containment and safe handling of varied substances at temperatures from -10C to +120C.

Engineered for Efficiency and Safety

Every tank features robust construction, custom flanged/BSP/NPT inlet and outlet options, and essential safety features like lockable manholes, level indicators, vents, ladders, and handrails. Automation and optional PLC controls facilitate seamless operation, while meticulous manufacturing standards guarantee leak-proof and easy-to-maintain solutions. With tailored capacities and insulation options, users can rely on these tanks for consistent performance.

FAQs of Storage Tanks:

Q: How do I choose between a polished or matte surface finish for my storage tank?

A: The choice depends on your aesthetic preference and the environmental conditions. Polished finishes are easier to clean and ideal for industries with strict hygiene standards, while matte finishes can reduce glare and may be preferred in certain industrial settings.Q: What types of liquids can these storage tanks accommodate?

A: These tanks are suitable for storing a variety of liquids, such as water, oils, chemicals, and other industrial fluids, thanks to their corrosion-resistant, leak-proof construction and customizable materials.Q: When is insulation recommended for a storage tank?

A: Insulation, such as PUF or Glasswool, is advisable when storing liquids that are sensitive to temperature changes or when maintaining internal temperatures is crucial, particularly in environments with extreme temperatures.Q: Where can these storage tanks be installed?

A: The tanks are designed for versatile installationindoors or outdoorsthanks to their robust construction and optional corrosion-resistant finishes. The configuration can be adapted to fit available space and operational needs, whether vertical or horizontal.Q: What is the process for customizing inlets, outlets, and manhole covers?

A: Customers can specify their requirements for inlet and outlet typesflanged, BSP, or NPTas well as manhole cover design. Our engineering team will incorporate these preferences during manufacturing, ensuring each tank meets site-specific installation criteria.Q: How does the automatic feature with PLC control benefit tank usage?

A: Integrated PLC control allows for automated monitoring and operation of tank parameters, which improves efficiency, ensures safety, minimizes manual intervention, and supports precise process management for industrial applications.Q: What are the advantages of using stainless steel or mild steel tanks?

A: Stainless steel provides superior corrosion resistance, longer service life, and ease of maintenance, making it ideal for corrosive liquids. Mild steel, while more economical, is suitable for less demanding applications and can be paired with protective coatings for added durability.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें