Process Reaction Vessels

उत्पाद विवरण:

- टाइप करें Process Reaction Vessel

- एप्लीकेशन Chemical, Pharmaceutical, Food Processing, Petrochemical, Paint and Dye, Fertilizer industries

- मटेरियल Stainless Steel, Mild Steel, Hastelloy, Alloy Steel

- क्षमता 500 L to 30,000 L

- वज़न Customizable as per capacity

- आयाम (एल* डब्ल्यू* एच) Custom Fabricated as per requirement

- शर्त

- Click to view more

प्रोसेस रिएक्शन वेसल्स मूल्य और मात्रा

- यूनिट/यूनिट

- 1

प्रोसेस रिएक्शन वेसल्स उत्पाद की विशेषताएं

- Stainless Steel, Mild Steel, Hastelloy, Alloy Steel

- Process Reaction Vessel

- 500 L to 30,000 L

- Custom Fabricated as per requirement

- Chemical, Pharmaceutical, Food Processing, Petrochemical, Paint and Dye, Fertilizer industries

- Customizable as per capacity

प्रोसेस रिएक्शन वेसल्स व्यापार सूचना

- 10 प्रति सप्ताह

- 4-5 हफ़्ता

- नालीदार बॉक्स में पैकिंग, सिकुड़ते हुए रैपिंग और लकड़ी के बक्से उपलब्ध हैं।

उत्पाद विवरण

Being an ISO 9001:2008 certified organization, our forte is to manufacture and export an exclusive array of Process Reaction Vessels. Offered in different capacities form 50 liters to 1,00,000 liters, these vessels are broadly used for storing gases, chemicals and acids under high temperature and pressure in various industries including Pharma, chemical, oil & refineries and gas. Made using optimum grade stainless steel and silicon, our Process Reaction Vessels are regarded for their attributes like leak proof nature, high temperature resistance and low maintenance. We offer these vessels at a reasonable price.

Specifications -

- This Process Reaction Vessels are capable to utilize optimum level of Gases.

- Highly Productive due to higher mass transfer rates

- The structure of Process Reaction Vessels are very simple shape & scientifically

- We design Process Reaction Vessels as per process parameters like clean-ability and product impurity profile

- We use high quality raw materials as well as cutting age technology in order to manufacture Process Reaction Vessels

- We follow International quality standards in order to meet quality standards

- These products are maximum performer, easy maintenance and robust quality therefore more demand able in market

- The finishing of this product is nice and durable

- Its motor is AC and that have constant rotating speed

- These products can be customized as per clients requirements

Area of Application -

- Pharmaceuticals Industry

- Petrochemical Industry

- Chemical Industry

- Oil Refineries

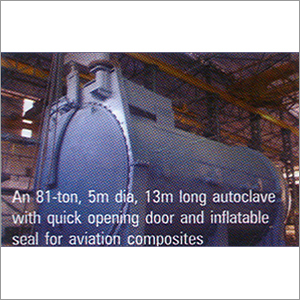

Technical Specification

|

Capacity Range |

214m3 |

|

Diameter |

5000 mm |

|

Length |

13000 mm |

|

MOC |

SA516Gr.70 |

|

Design Pressure |

kg/cm2 8/F.V. |

|

Hydrotest Pressure |

15 Kg/cm2 |

|

Design Temperature |

160oC |

|

Empty Weight |

72 Tons |

|

Pressure Range |

10 to 150 kg/cm/g |

|

Temp. Range |

1000C to 3500C |

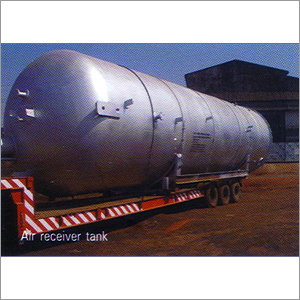

Product details

|

Design |

ASME SECTION VIII DIV 1 |

|

MOC |

CS TO IS 2062 / SA516 GR B |

|

Herder Pipe |

To suit client requirement |

|

Many way |

Standard bolted manway with davit arm for higher sizes 9.5 Kg/cm2 max. |

|

Other Options |

Custom made mounting supports, Peep holes, Pressure Gauges Can be supplied on request |

|

Dish arrangement |

Welded dish end arrangement is standard. Flanged dish can be supplied for smaller sizes on customer request. |

|

NDT Tests |

LPT test on all welds, Ultrasonic tests on Material, Radio graphic test as per relevant standards and to clients requirement. |

|

Painting |

Epoxy paint with suitable primer Upto 120 microns is standard. |

Versatile Agitation and Advanced Design

These reaction vessels are available with multiple agitator typesincluding anchor, turbine, propeller, and magneticallowing adaptation to various process viscosities and mixing requirements. The vessels are meticulously engineered following respected standards such as ASME, DIN, IS, or can be tailored for specialized needs. Their nozzle configuration, sealing types, insulation options, and installation flexibility (floor or skid-mounted) provide significant adaptability for any application.

Optimal Performance in Demanding Conditions

Engineered for high-pressure (up to 25 bar) and high-temperature (up to 300C) environments, these vessels ensure reliable operation even in the most challenging industrial settings. Corrosion-resistant materials and a choice of mirror, matt, or polished surface finishes guarantee durability, hygiene, and ease of maintenanceessential for applications in chemical, pharmaceutical, and food industry sectors.

FAQs of Process Reaction Vessels:

Q: How do I choose the right agitator type for my process reaction vessel?

A: Selecting the appropriate agitator (anchor, turbine, propeller, or magnetic) depends on your processs viscosity, mixing intensity, and product homogeneity requirements. Anchors suit high-viscosity fluids, turbines support vigorous mixing, propellers ensure efficient flow, and magnetic options provide leak-free operationideal for sterile and hazardous environments.Q: What materials are available for constructing these process reaction vessels, and how do they benefit different industries?

A: Our vessels can be fabricated from stainless steel, mild steel, hastelloy, or alloy steel. Stainless steel and hastelloy offer exceptional corrosion resistance, making them suitable for chemical and pharmaceutical industries. Mild steel is cost-effective for less aggressive applications, while alloy steel provides durability in specialized environments.Q: When should I opt for a jacketed vessel and what is its advantage?

A: Jacketed vessels are recommended whenever your process involves precise temperature controleither for heating or cooling. Using thermal transfer fluids, the jacket allows consistent process temperature maintenance, critical for sensitive or exothermic reactions typical in chemical, pharmaceutical, and food processing sectors.Q: Where can these vessels be installed, and what mounting options are available?

A: Our reaction vessels are versatile in installation, either floor-mounted or skid-mounted depending on space, mobility, and operational requirements. Skid mounting is ideal for easy transport or modular integration within larger process systems.Q: What design standards do you follow and can you provide customized solutions?

A: We design vessels to international (ASME, DIN) and Indian (IS) codes, ensuring global compliance. Custom designs are available to match unique process requirements, including specific nozzle arrangements, dimensions, and capacities.Q: How does the surface finish affect the vessel performance and maintenance?

A: The choice between mirror, matt, or polished finishes influences hygiene, cleanability, and product adherence. Mirror finishes are preferred in sterile applications like pharmaceuticals, while matt or polished finishes are suited for general industrial processes, simplifying cleaning and reducing contamination risks.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें